In the realm of chemical manufacturing, efficiency is paramount. It not only ensures profitability but also drives innovation and sustainability. SAPDMA, or Stearamidopropyl Dimethylamine, stands as a prime example of a chemical compound that has garnered attention due to its versatile applications across various industries. However, for businesses involved in its production, understanding and optimizing SAPDMA production costs are key to maintaining competitiveness in the market.

Request For Free Sample: https://www.procurementresource.com/production-cost-report-store/sapdma-stearamidopropyl-dimethylamine/request-sample

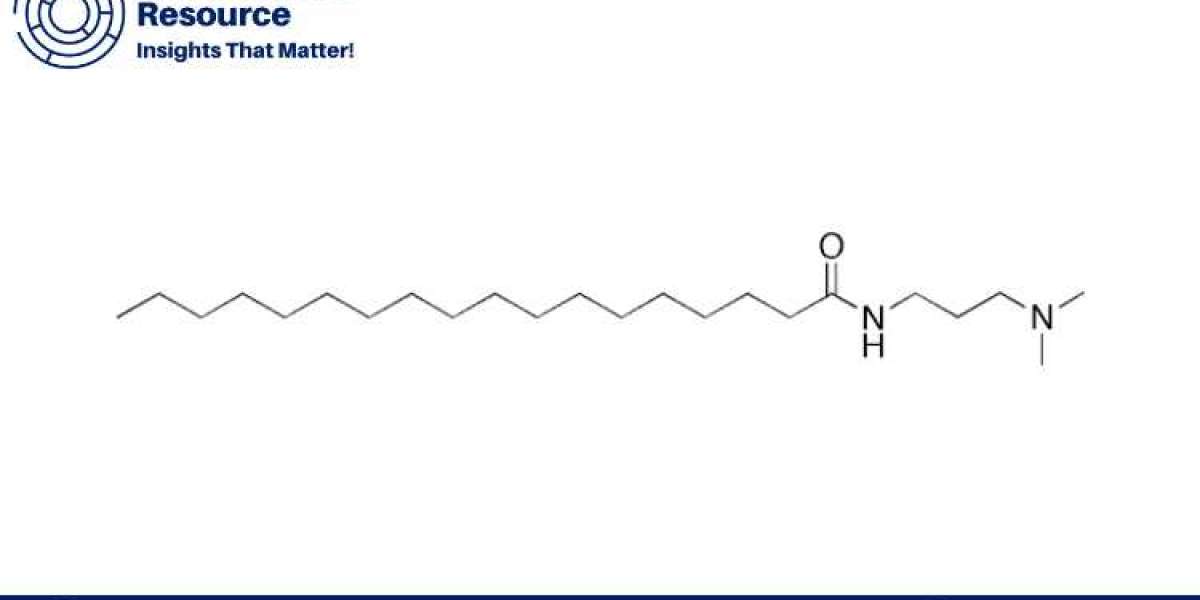

What is SAPDMA?

SAPDMA, known by its chemical name Stearamidopropyl Dimethylamine, is a crucial ingredient utilized in the manufacturing of personal care products, such as shampoos, conditioners, and lotions. It serves as a conditioning agent, imparting smoothness and softness to hair and skin. Additionally, SAPDMA finds applications in the production of industrial chemicals, further diversifying its utility.

The Importance of Production Cost Analysis

For companies engaged in SAPDMA production, analyzing production costs is a multifaceted process. It involves assessing various factors, including raw material expenses, energy consumption, labor costs, equipment maintenance, and regulatory compliance. Understanding these costs is imperative for optimizing production processes, enhancing efficiency, and ultimately maximizing profitability.

Raw Material Procurement

One of the primary cost components in stearamidopropyl Dimethylamine production is the procurement of raw materials. Stearamidopropyl Dimethylamine itself is derived from readily available raw materials, including stearyl alcohol, dimethylamine, and propylene oxide. However, fluctuations in the prices of these raw materials can significantly impact production costs. Therefore, maintaining stable supplier relationships and exploring alternative sourcing options are crucial strategies for cost containment.

Energy Consumption and Process Efficiency

Energy-intensive production processes are common in chemical manufacturing, and stearamidopropyl Dimethylamine production is no exception. Analyzing energy consumption patterns and implementing energy-efficient technologies can substantially reduce operational costs while simultaneously mitigating environmental impact. Process optimization, such as employing catalysts or adjusting reaction conditions, can enhance yield and minimize energy requirements, further improving cost efficiency.

Labor Costs and Automation

Labor costs constitute a significant portion of production expenses. Investing in workforce training programs to enhance productivity and implementing automation technologies to streamline repetitive tasks can help minimize labor costs. Automation not only increases efficiency but also ensures consistency in product quality, contributing to long-term cost savings and customer satisfaction.

Equipment Maintenance and Upkeep

Maintaining production equipment is essential for preventing downtime and ensuring uninterrupted operations. Implementing proactive maintenance schedules and investing in modernization initiatives can minimize equipment failures and prolong asset lifespan, ultimately reducing maintenance costs. Additionally, incorporating predictive maintenance technologies can identify potential issues before they escalate, optimizing resource allocation and enhancing cost efficiency.

Regulatory Compliance and Environmental Sustainability

Adhering to stringent regulatory standards is non-negotiable in chemical manufacturing. Compliance-related costs, including obtaining permits, conducting environmental impact assessments, and implementing safety protocols, must be factored into production cost analyses. Embracing sustainable practices, such as waste reduction, recycling, and resource conservation, not only fosters environmental stewardship but also drives cost optimization by minimizing raw material usage and disposal expenses.

The Role of Production Cost Reports

Production cost reports serve as invaluable tools for decision-making and performance evaluation. These reports provide comprehensive insights into cost structures, identify areas for improvement, and facilitate data-driven strategies for cost reduction and optimization. Regular review and analysis of production cost reports enable businesses to adapt to market dynamics, seize opportunities, and maintain competitiveness in the ever-evolving chemical industry landscape.

In conclusion, understanding and optimizing SAPDMA production costs are imperative for chemical manufacturers seeking to thrive in a competitive market environment. By adopting a holistic approach encompassing raw material procurement, process efficiency, labor management, equipment maintenance, regulatory compliance, and sustainability practices, companies can unlock efficiency, drive innovation, and achieve sustainable growth in the dynamic world of chemical manufacturing.